FieldShield StrongFiber Cable

Designed to simplify the placement of fiber, FieldShield StrongFiber reduces the cost of any fiber deployment while providing industry leading protection when combined with FieldShield Microducts. StrongFiber is pulled through microduct at turn-up maximizing installation efficiency. In the event of a duct or fiber being damaged or for future upgrades, the fiber can be easily pulled from the microduct. The duct is then repaired and a new FieldShield StrongFiber assembly is pushed or pulled through the microduct for a fast and cost-effective restoration or upgrade.

StrongFiber may be used in place of a traditional patch cord for reduced cable pileup within the route-path of new or traditionally oversubscribed frames within a central office, headend, data center or remote hut. StrongFiber is 85% smaller than traditional 3 mm patch cords and 69% smaller than 1.2 mm patch cords. The reduced size and weight makes the fiber less susceptible to micro-bends and makes it much easier to store using any fiber management element.

Product Details

FieldShield StrongFiber is a durable high tensile strength fiber when compared to other fibers of its size. It is suitable for both indoor and outdoor environments when used in FieldShield Microduct. Manufactured with premium bend-insensitive fiber, FieldShield StrongFiber offers high tensile strength to resist damage to the fiber during installation in the FieldShield Microducts. When terminated with a FieldShield Pullable Connector, the FieldShield StrongFiber can be quickly deployed in FieldShield Microduct, reducing installation time drastically.

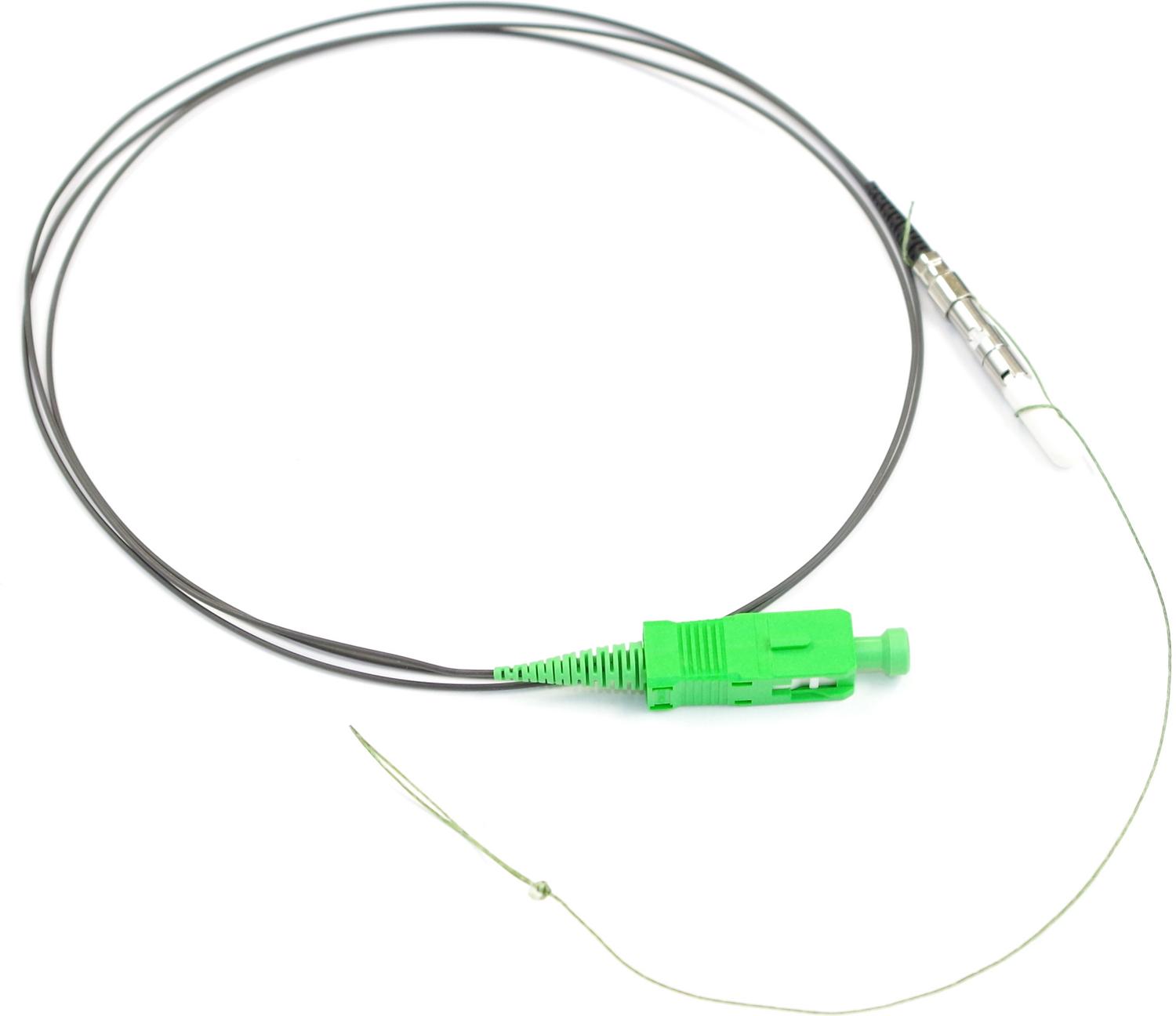

Connector options for this product include FieldShield SC and LC Pushable Connectors or FieldShield MPO Pushable Connector.

FieldShield StrongFiber Deploy Reel

The FieldShield StrongFiber Deploy Reel is a 4.5” x 1” (114.30 mm x 25.40 mm) spool designed to hold up to 300 feet (91.44 m) of FieldShield StrongFiber. It has an integrated bulkhead and pre-mated adapter that can easily be mounted into a small form factor fiber management element. The small form factor of the 900 μm fiber makes slack storage minimal and easy to accommodate, while the exceptional pull strength of StrongFiber makes it craft-friendly and easy for the technician to handle without fear of fiber damage. Less cable weight means reduced co-efficient of friction (COF). This results in quicker installations because there is minimal friction as the cable is pulled through bends and turns throughout the microduct routepath. Reducing the size requirements of the access point (above or below grade) provides a more aesthetically pleasing solution.

Features & Benefits

Integrity

- StrongFiber fiber cable designed, tested and certified to Telcordia GR-20

- Available in singlemode

- Supports all SC and LC connectors

Protection

- Bend-insensitive (G.657.A2) fiber protects optical signal with minimal to zero attenuation

- Lightweight with low coefficient of friction to maximize pull distances

Access

- Standard color is black

- Tech-friendly 900 μm fiber

- Suitable for all types of indoor implementations

Investment

- Quick and easy deployment allows capital investment to be aligned to customer take rates

Technical Specifications

| Specification | Description |

| Fiber | OFS All Wave Flex + Fiber or equivalent |

| Water Peak | ZWP (Zero Water Peak) |

| Bend-Insensitive | Meets G.657 A2 |

| Color | Black |

| Length | Up to 300 feet (91.44 m) |

| Fiber Count | Single Fiber |

| Pullable Connectors | FieldShield SC/UPC, SC/APC |

| Standard Connectors | SC/UPC, SC/APC, LC/UPC, LC/APC |

| Mode | Singlemode |

| Outside Diameter | 900 µm |

| Material | Thermoplastic Blend, Low Smoke/Fume, Non-Halogen Flame Retardant |

| Rating | OSP Temperature Rated |

| Bend Radius | 10 mm Minimum |

| Operating Temperature | -40°F to 176°F (-40°C to 80°C) |

| Installation Temperature | -14°F to 158°F (-26°C to 70°C) |

| Installation Tension | 18 lbs. (8.16 kg) |

Physical Glass Characteristics

| Characteristic | Description |

| Fiber Size | 250 µm |

| Clad Diameter | 125.0 +/- 0.7 um |

| Core/Clad Concentricity Error (Offset) | ≤1% |

| Coating Diameter (Uncolored) | ≤ 0.5 μm maximum, < 0.2 μm typically |

| Coating-Clad Concentricity Error | 235 - 245 µm |

| Tensile Proof Test | (Offset) ≤ 12 μm |

| Tensile Proof Test | 100 kpsi (0.69 GPa) |

| Coating Strip Force Range | ≥ 0.3 lbf < 2.0 lbf (≥ 1.3 N < 8.9 N) |

Performance Specifications

Minimum Performance Specifications for Terminated Singlemode Connectors

| Connector Type | Ferrule Material | Polish Type | Ins. Loss Typical (dB) | Max. Ins. Loss (dB) | Min. Ret. Loss (dB) |

| SC | Ceramic | UPC | 0.15 | 0.20 | 55.00 |

| LC | Ceramic | UPC | 0.15 | 0.20 | 55.00 |

| SC | Ceramic | APC | 0.18 | 0.20 | 65.00 |

| LC | Ceramic | APC | 0.18 | 0.20 | 65.00 |